Content

ServeCAST™

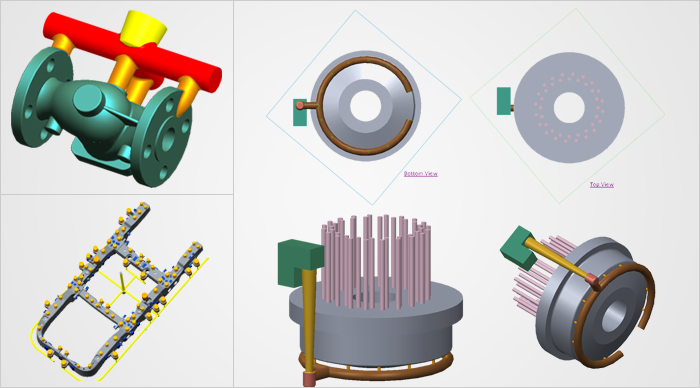

The Service Portfolio, branded under the name "ServeCAST™", includes Casting Simulation & Methoding Services with SoftCAST™ and Technology Mapping. For Castability and Method Assessment, Quality & Yield Improvement, and Method Optimization.

DFM (Design for Manufacturability) service is provided to OEMs, casting designers and buyers, and to Foundries, for assessing and optimizing the design of cast components from a manufacturability perspective.

Casting Simulation & Methoding Services:

Check your casting and predict shrinkage, porosity defects - without incurring tooling costs or waiting for trials. Check for other likely defects - tears /cracks, sand fusion, scab /drop, and inclusions. Assess your method for defect potential. Optimize it for quality and yield improvement. The consulting services are performed using SoftCAST™ - the intelligent software for casting simulation and method analysis, backed by 50+ years of research and industry validation on all major cast metals and processes.

Range of Service

- For all cast metals /alloys and processes

- For castings of all weights, section thicknesses and moduli

- For all Foundries, Die-casting units & Tool makers

- For all Casting Designers and Buyers /Users

Types of Service

- Castability Analysis

- Existing Method Assessment (includes 1)

- Method Design /Improvement - Quality Improvement (includes 2)

- Method Design /Improvement - Yield Improvement (includes 1, and 3 if necessary)

- Method Optimization (includes 1, and 2 /3 if necessary)

Please contact us to avail the above and other special services such as Technology Mapping, Method Optimization with Technology Mapping, and DFM services.