Content

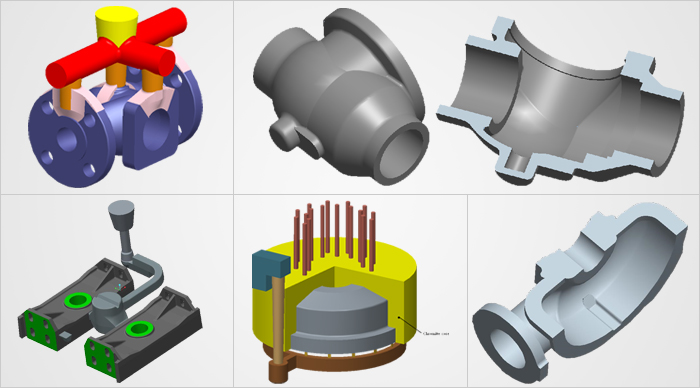

SoftCAST™

A multi award-winning software, SoftCAST™ is a simulation, method design and assessment system for foundries. It simulates casting behaviour during manufacture. It predicts potential defects and quality issues, both as driven by the cast component design and by its method design. The design modules in SoftCAST™ facilitate easy development of new methods and optimization of existing methods; they enable method improvement and development without shop floor trials!

Apart from a fast and accurate simulation system, SoftCAST incorporates Feeding and Gating System Design modules for the various cast processes and alloys, an in-built CAD system called AutoLayout that automates the creation of 3D solid models of the Method Layout / Tree, and an Assessment & Report Module that generates HTML and indexed PDF Reports on the entire casting project. The AR module enables quality and yield improvement without shop floor trials.

SoftCAST™ is built on a revolutionary technology and developed in collaboration with the foremost Science and Technology Institution in India - the Indian Institute of Science Bangalore (ranked on par with the best in the world). It is technology that was created to meet the real life problems of foundries. It helps you do away with the elaborate thermo-physical data route that traditional thermal analysis requires.

Through a host of features, SoftCAST™ delivers one-shot productivity, quality, cost-effectiveness and convenience to your foundry. Yet at the same time the system is very easy to use. To date, it has been tried, tested and installed in a large number of foundries both in India and abroad. Thousands of castings of various alloys and cast processes and method designs have been successfully analysed /developed /optimized with SoftCAST™.

SoftCAST™ incorporates indicators that assess the potential for Quality (i.e. defects) and Yield achievement and improvement. Its Comparative Assessment and Report feature enables method improvement without shop floor trials. Its advanced Feeding and Gating System Design modules generate both Safe & Optimal designs. Unique among them are the Feeding/Gating System design module for IC and LFC, FSD module for the graphitic irons based on Dr. Karsay’s principles, and GSD modules for both horizontally parted and vertically parted molding systems. These Design modules cater separately to the different categories of cast metals /alloys and processes, as driven by their solidification behaviour.

SoftCAST™ Applications:

Modules are available for most Casting Processes - Sand Casting (all sub-processes), GDC (including Tilt GDC), LPDC, Investment Casting (both Lost Wax & Lost Foam), Shell Molding, Vacuum Molding, LFC/Full Mold, Block /Ceramic Mold, HPM (both horizontally and vertically parted).

Modules are available for all Cast Metals and Alloys - Steels (including high alloy, stainless, duplex/ super-duplex), grey cast irons, ductile irons, malleable irons, Ni and Super alloys, alloy cast irons (such as HCHC, Ni hard & Ni resist), aluminium and magnesium alloys, titanium and copper alloys, zinc and lead alloys, and ceramics.

The System is suitable for all production situations - Jobbing & Lot/ Batch/ Mass production foundries, simple & high complexity castings, single & multi cavity mold designs/ patterns, and low to very high casting weights, and of any section thicknesses.

Key Features & User-friendliness:

- Complete System: SoftCAST™ contains all the Simulation and Method Design Modules required by a foundry to perform casting and method simulations, to design and develop methods, and to improve Quality and Yield.

- Unique Modules: Apart from the above modules, SoftCAST™ incorporates several unique modules. [contact us for details]

- Speed, Accuracy: SoftCAST™ is extremely fast (possibly the fastest system today), which means more simulations in a given time period. At the same time, accuracy is not sacrificed!

- Data requirements: Far less requirement of elaborate, extensive data.

- All in all, the above features impart a high degree of utility & user-friendliness - for quick implementation and regular use.

Major direct benefits to the foundry, secured through SoftCAST™:

- Reduction in total time to develop and establish a method. Quick and easy method development and proving means faster deliveries

- Minimisation of shop-floor trials, initially, leading on to their elimination in due course

- Elimination or Minimisation of defects, rejections & rework /repair

- Yield improvement & method optimization

- Positive Outcomes from the above: Reduction (and hence Savings) in Material, Energy & Labour; Reduced Carbon Footprint; Carbon Credits gained

- Consistency in methoding - hence elimination of variations

- Improved credibility in the eyes of the customer - hence repeat orders and continuing business with lesser market acquisition costs and effort

- Improved knowledge /skill level of methods engineers - hence better performance

SoftCAST™ Support:

Apart from a powerful system that meets all the needs of the foundry, we provide industry-leading support & services. And as you would appreciate, strong support is essential to ensure success of the implementation and regular use of such high-tech systems.

- Complete initial onsite support - installation, operational training, and technical training.

- Subsequent support: Regular support thereafter, including local 1st level support where available. Tel. /Email, online VoIP /video conference& desktop, Refresher courses and Review Sessions (onsite and /or at Bangalore).

- Product Upgrades, Updates.

- Special Value-added service: Assured Payback Service, Optimization Services.

- Other value-added support /services: methoding support; additional training - methoding, foundry technologies, basics of heat transfer, flow and design; 3D modelling support.